Phone: 8613902467535

Phone: 8613902467535

Address: The third floor of Building A, Weixin Industrial Park, Shiyan shitoushan Industrial Zone, Bao'an District, Shenzhen.

Cell phone: 8613902467535

Phone: 86755-27935245

E-mail: sales@cptele.com

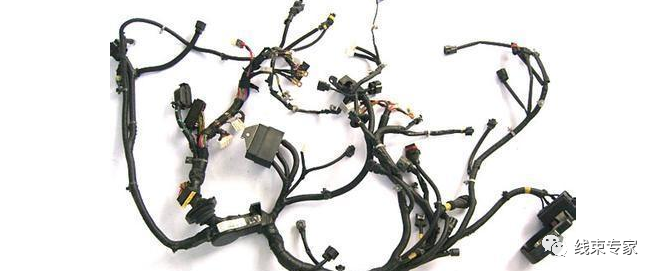

Material, function and process production of wire harness products

Release date: 2021/5/8 14:44:12 | Publisher: Shenzhen Cptele Electronics Co., Ltd

The wire requirements in various parts of the automotive wiring harness are strict and distinctive. Most of them are from the aspects of its electrical properties, temperature resistance and material emission, such as: the wire of the engine wiring harness must be high temperature, oil resistance, vibration resistance, and friction resistance; The wires on the automatic transmission are high temperature resistant, hydraulic oil resistant, and have good stability; The wiring harness on the trunk lid must be selected to maintain its innate elasticity in a low temperature environment, so a cold elastic wire should be selected to ensure its normal operation; ABS wiring harness needs high temperature conditions, generally choose a high temperature environment of 150-200 °C, hard insulation, wear resistance, but to choose more than 133 stranded wires. The functions of automotive wiring harness products can be divided into two types, one is the power line that carries the power of the drive actuator, and the other is the signal line that transmits the input command of the sensor. A thick wire that has the function of transporting a large current is a power line, and a thin wire that has the function of not carrying electricity is a signal line.

With the changes in social needs and the rapid change of science and technology, the functions of automotive modules are increasing, electronic technology has been widely used in modern new cars, and electronic control systems are closely related to automotive wiring harnesses. As mentioned at the beginning of this article, the wiring harness acts like blood vessels in the human body and is an essential element. There is such an analogy: the ECU and other control modules of the car are equivalent to the brain of the car, the various sensors on the car are equivalent to sensory neurons, the executive elements are equivalent to motor organs, and the wiring harness is nerves and blood vessels.

At the same time of combining science and technology with the multi-function of the car, there are also many contradictions and problems, such as: how to effectively and reasonably arrange in the limited car space, so that the car wiring harness can play the maximum role and function. The process production of automotive wiring harness can generally be divided into four steps: one is the wire opening and crimping process, and the other is the pre-assembly process; the third is the final assembly process; Finally, there is the post-assembly process. The open-line process needs to be careful and rigorous, its accuracy affects the entire production schedule, and the slightest error will affect the production efficiency. Therefore, at present, most wire harness factories use fully automated line opening equipment; The crimping process requires the crimping parameters and the required applicator to be determined according to the customer's crimping standard and terminal type.

Since the crimping quality is directly related to the electrical performance, this station is a key station, which needs to have a crimping operation manual that indicates the special characteristic requirements, and randomly check the crimping quality online in proportion to form a characteristic control chart in accordance with the specified process; Regarding the pre-assembly process, the primary task is to make KIT into the plastic parts of the open wire crimped according to the process instructions, which will help reduce the investment cost of the final assembly line equipment, reduce the difficulty of the final assembly operation, and reduce the final assembly operators. For simple automobile wiring harnesses, the pre-installation can be directly canceled, and for complex automotive wiring harnesses, pre-installation stations are generally set up first; After that, the final assembly process, according to the process, the pre-assembled wiring harness is arranged on the final assembly tooling board in an orderly manner, and the wiring harness is finished, the tape is wound, the karting is bundled, and the rubber parts are installed. Finally, there is the post-assembly process, which includes the production process of mounting bracket, live detection, full size inspection, and bundling and packaging.

【 Return 】 【 Print 】 【 Close this window 】